Bulk Bag Unloaders

And FIBC Unloaders/Super Sack Unloaders

Bulk bags, also known as FIBCs or Super Sacks, have been utilized since the 1960s. Due to their cost-effectiveness, recyclability and suitability for a wide range of free-flowing materials, they have become a fundamental choice for various industries. Our bulk bag unloaders are designed to assist you in processing materials with safety and efficiency, simultaneously minimizing dust and waste.

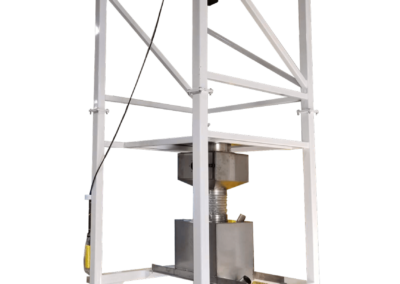

Bulk Bag Unloader Options

Pneumatic bag massagers to aid in material flow

Rotary airlock discharge

Pneumatic bag pinch bars for partial discharging

Vacuum take-off boxes

Iris valve, 14”

Screw conveyor discharge

Steel or stainless receiving hoppers

Work platforms

Loss-in-weight or gain-in-weight systems

Safety guarding

Receiving hoppers (steel, stainless, aluminum)

Extended rail options

Integrated dump chutes and bag dump stations

NEMA fixed operator panels

Bulk Bag Unloader Models

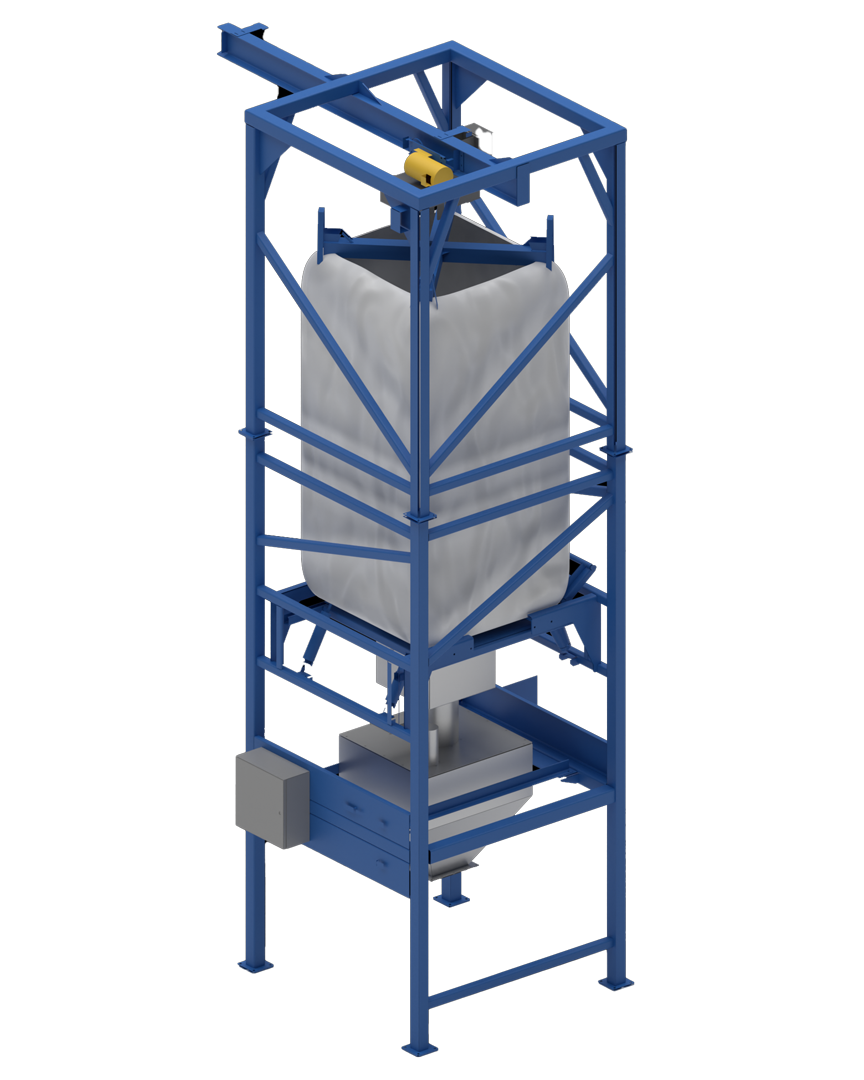

Hoist & Trolley: Model BU-4000

Standard Features:

- Heavy duty steel construction

- 4000 lb capacity

- Cantilevered I-beam monorail

- CM Hoist & Trolley:

- Yale 2-ton chain hoist

- H4 heavy duty rated

- 460V, 3PH

- NEMA 4X operator pendant

- Chain container

- Hoist travel limit switches

- 16fpm lift speed

- Trolley travel limit switches, AB

- 35fpm trolley speed

- H-style bag lift frame

- Bag support pan

- Untie chamber

- Foot pads

- Industrial epoxy paint

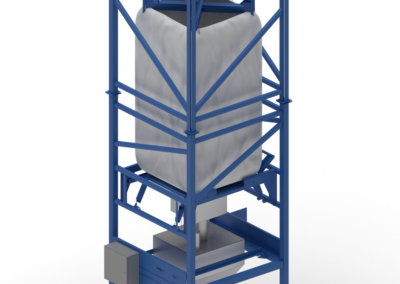

Forklift Load: Model BU-2000

Standard Features:

- Heavy duty steel construction

- 4000 lb capacity

- Adjustable height frame for multiple size bags

- Bag lift frame w/ integral fork pockets and loop hooks

- Bag support pan

- Untie chamber

- Foot pads

- Industrial epoxy paint

Let's Talk

Ready to get started? Give us a call at (616) 283-2506 or send us an email using our form.

"*" indicates required fields