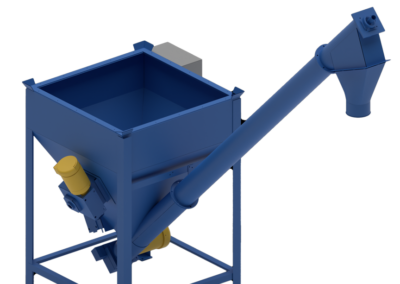

Power Hoppers & Screw Conveyors

Power hoppers store and dispense various types of materials in a controlled manner, using advanced mechanisms and technologies, such as screw conveyor systems, to regulate the flow rate and prevent overloading. By automating the loading and unloading tasks, power hoppers enhance operational efficiency and improve safety.

Options & Features

VFD

Bin guard, 3” x 3”

Mechanical agitator assy

Bag break grate w/ slitter blade

Carbon or Stainless steel

0 to 60 degree inclined

Splash guards, 3-sides

Caster frame w/ auger support

Models

Other sizes and configurations available.

6” Solid Core Auger, 7” Tube

Standard Features:

- PB-645, 45 deg, 230/460VAC / 3PH, 280 cf/hr

- PB-660, 60 deg, 230/460VAC / 3PH, 320 cf/hr

- 44 “x 44” x 46” tall hopper body (20 cf)

- TEFC Premium Efficiency Motor, Baldor

- Direct gear drive, NORD

- NEMA 12 control panel w/ AB components

*throughput rates below are based on plastic pellets

4” Solid Core Auger, 5” Tube

Standard Features:

- PB-445, 45 deg, 230/460VAC / 3PH, 150 cf/hr

- PB-460, 60 deg, 230/460VAC / 3PH, 180 cf/hr

- 44 “x 44” x 46” tall hopper body (20 cf)

- TEFC Premium Efficiency Motor, Baldor

- Direct gear drive, NORD

- NEMA 12 control panel w/ AB components

*throughput rates below are based on plastic pellets

Let's Talk

Ready to get started? Give us a call at (616) 283-2506 or send us an email using our form.

"*" indicates required fields